Low-carbon aluminum

Primary aluminum with a carbon footprint that is one-third the industry average

EcoLum is primary aluminum with an emissions intensity1 that is one-third the industry average.2 Produced from smelters that use renewable energy and low-carbon alumina sources, EcoLum is offered in a full range of products, including billet, foundry, slab, wire rod, unalloyed high purity and P1020.

- EcoLum primary aluminum is produced with less than 4.0 metric tons of CO2e for every metric ton of metal, including both direct and indirect (Scope 1 and Scope 2) emissions from mining, refining, smelting and casting

- Cradle-to-gate carbon footprint data is third-party verified and available to customers.3

- EcoLum primary unalloyed aluminium cradle-to-gate carbon footprint is 4.5 metric tons of CO2e per metric ton of metal, aligned with International Aluminium Institute (IAI) cradle-to-gate carbon footprint methodology and guidance

- Products can be offered with certification from ASI

- Verified according to ISO 14025, and life cycle analysis per ISO 14044

- Corporate greenhouse gas (GHG) inventory calculations is third-party verified and consistent with ISO 14064

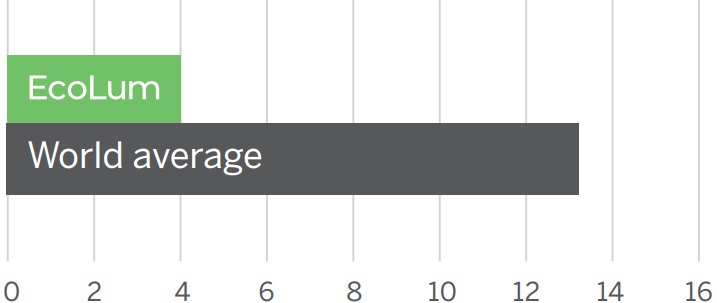

EcoLum emissions intensity vs. global average per metric ton of CO2e/metric ton of aluminum

CRU emission intensity data, 2024

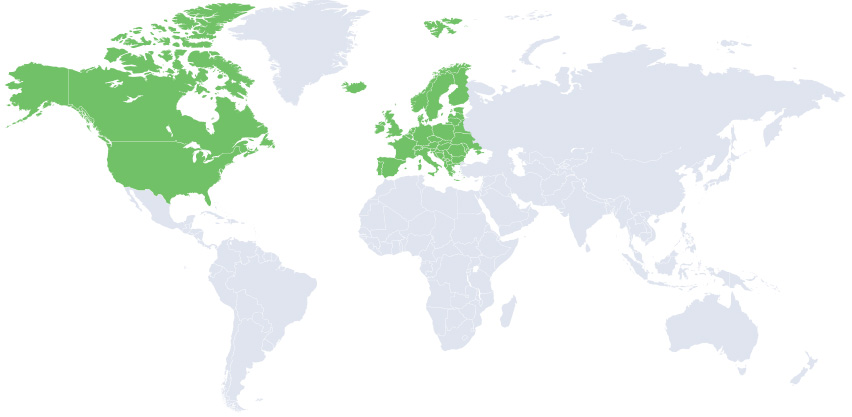

Region of production (smelting)

Low-carbon alumina

Alumina products from a refinery portfolio with average emissions intensity less than half

of the industry average2

The world's only low-carbon alumina brand, EcoSource, is delivered from a refinery portfolio with an average emissions intensity that is no more than 0.6 metric tons of carbon dioxide equivalents per metric ton of alumina produced, including both direct and indirect (Scope 1 and Scope 2) emissions from bauxite mining and alumina refining. Leveraging Alcoa's mine-to-refinery advantage, this emission intensity is less than half of the global industry average.2

- Available as smelter-grade (SGA) and certain non-metallurgical (NMA) grades

- Cradle-to-gate carbon footprint data is third-party verified and available to customers.3

- Products can be offered with certification from ASI

- Locations certified against international quality standard ISO 9001 and environmental standard ISO 14001

- Corporate greenhouse gas (GHG) inventory calculations is third-party verified and consistent with ISO 14064

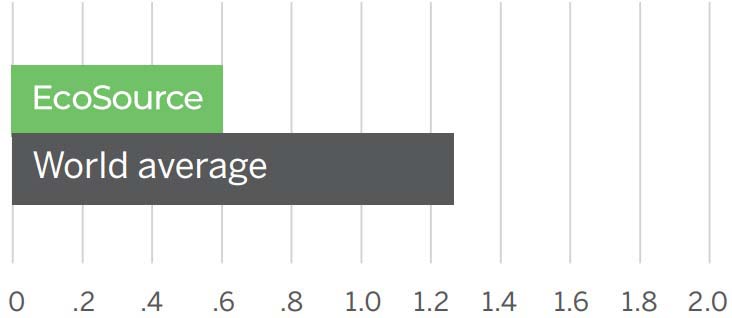

EcoSource emissions intensity vs. global average per metric ton of CO2e/metric ton of alumina

CRU emission intensity data, 2024

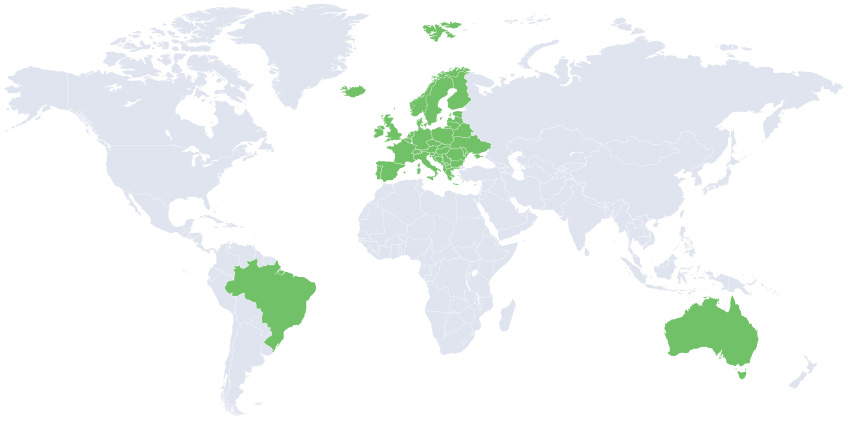

Region of production (refining)

Aluminum with recycled content

Aluminum with at least 50 percent recycled content, supporting the circular economy

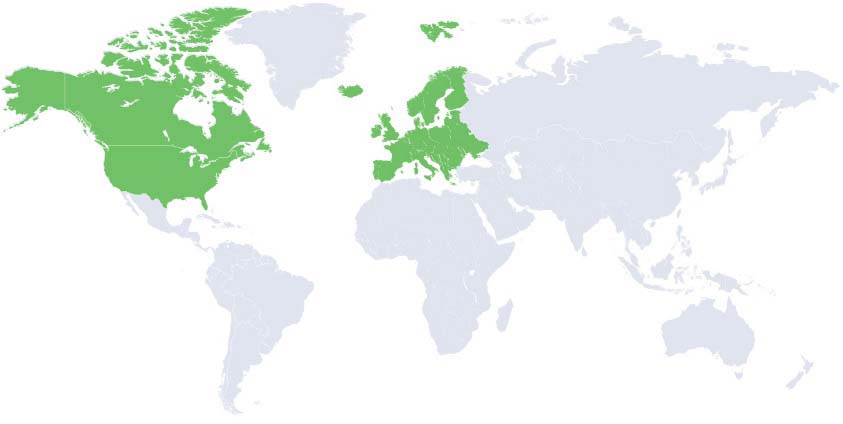

Aluminum's status as a nearly infinitely recyclable metal makes it a key enabler of the circular economy. EcoDura contains at least 50 percent recycled content,4 conserving significant amounts of energy and reducing the environmental impacts associated with producing virgin aluminum. EcoDura is manufactured in North America and Europe, using clean scrap from verified sources and is available to customers globally.

- EcoDura locations are ISO 9001 certified

- The product can contribute to LEED® certification points for sustainable building and construction projects

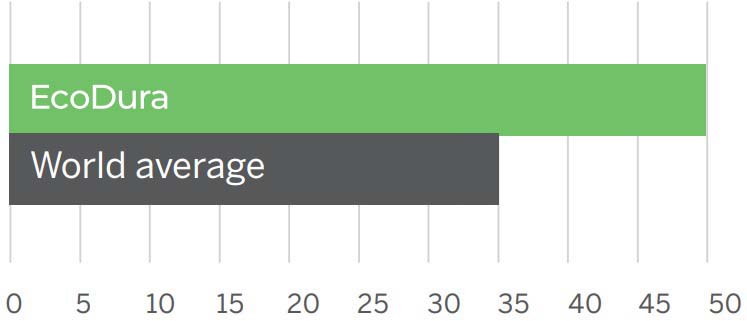

EcoDura recycled content vs. global average

Percent

International Aluminium Institute, 2021

Region of production (casting)

1 Scope 1 and 2 emissions from mining, refining, smelting and casting for EcoLum and from mining and refining for EcoSource. The emissions are reported in accordance with the International Aluminium Institute (IAI) Aluminium Sector GHG Protocol, addendum to the WRI/WBCSD GHG protocol, the WRI/WBCSD Calculation Tool for Direct Emissions from Stationary Combustion, and the WRI GHG Protocol Scope 2 Protocol.

2CRU emissions intensity data, 2024

3 Alcoa’s third-party verified EcoLum cradle-to-gate carbon footprint numbers have been calculated using a location-based scope 2 reporting approach aligned with EN15804+A2 and ISO14040 and ISO14044 requirements.

4 Pre-consumer scrap. Recycled content defined using credit allocation system at a product line and production facility level.